Start From Uncut Sheet

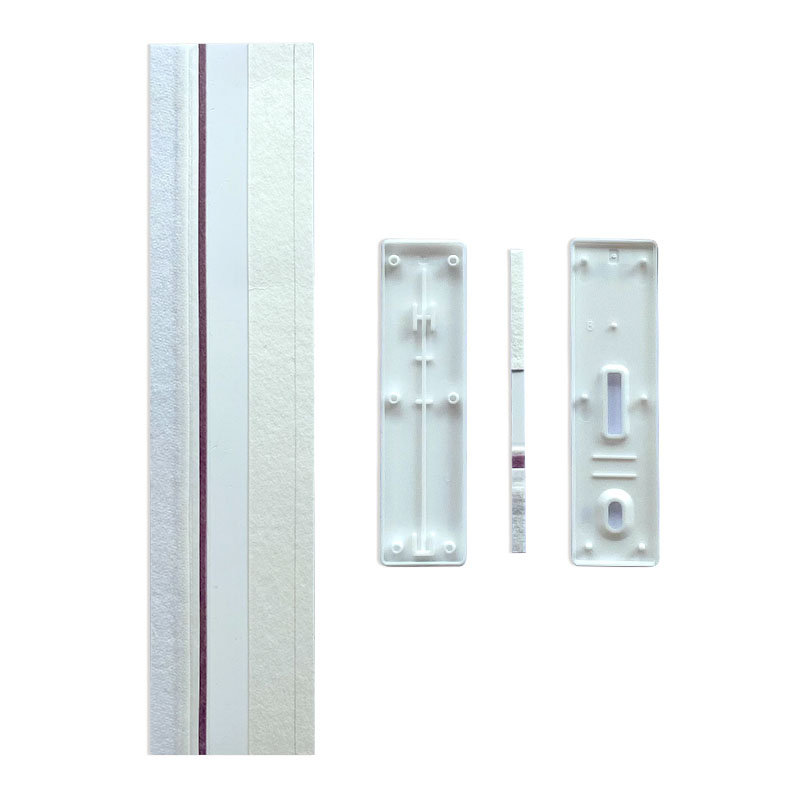

The rapid test uncut sheet refers to a sheet for diagnostic test devices that have not been cut into individual test strips or cassettes. Rapid diagnostic tests (RDTs) are often produced in a large and complete sheet format, with multiple components arranged properly in rows and columns.

Before being used for testing, the sheet is typically cut into individual test strips or cassettes. The uncut sheet format is used in the manufacturing and quality control of the rapid test devices.

Manufacturers of rapid tests use the uncut sheet format for a variety of reasons, including efficiency in production, cost savings, and easier quality control. It allows for a large number of test devices to be produced at once, which can increase production speed and decrease costs.

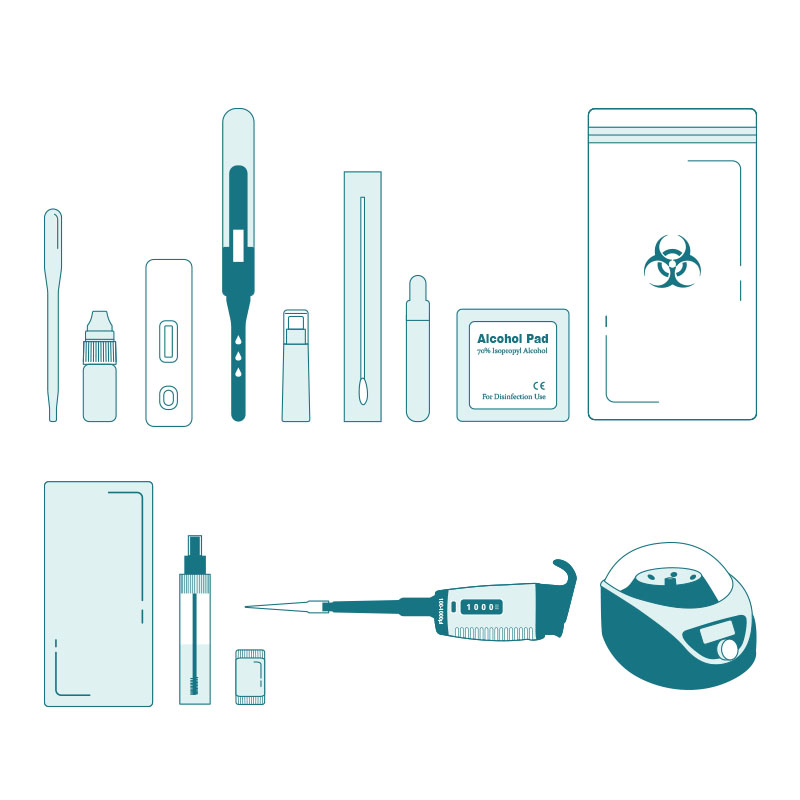

Once the uncut sheet is produced, it undergoes further processing, including cutting, assembly, and packaging, before being shipped to end-users such as healthcare providers, laboratories, or consumers.

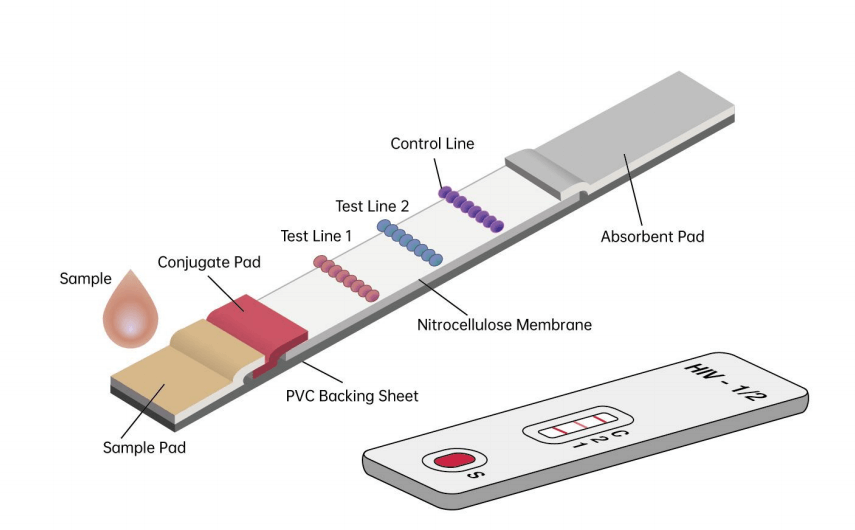

The uncut sheet is consisted of key components as below :

- Sample Pad

- Colloidal Gold Conjugate Pad

- NC Membrane

- Absorbent Pad

- PVC Backing Sheet

Please feel free to contact us immediately to request samples for your Uncut Sheet business before commencing the rapid test production.

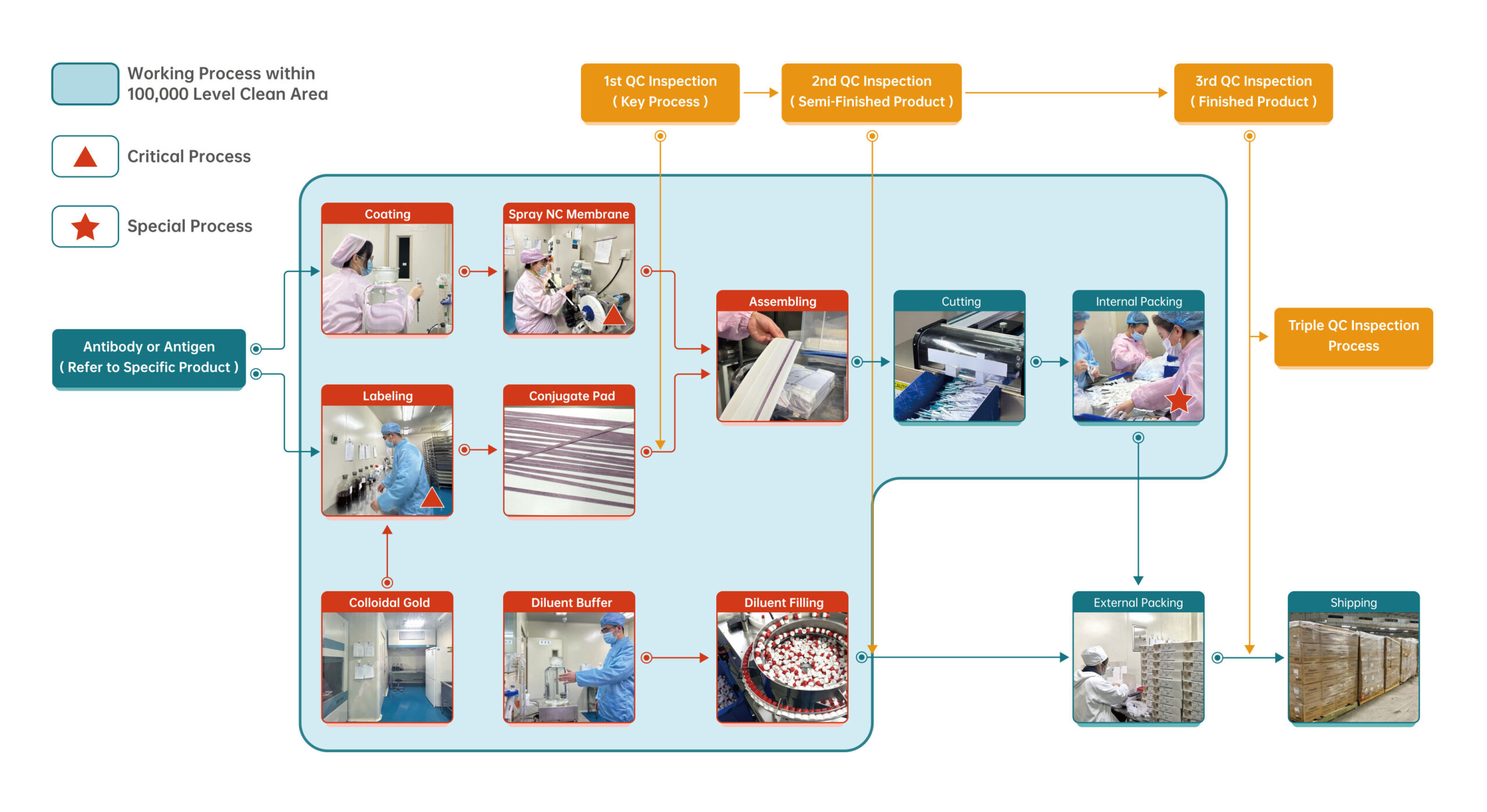

Production Process Flowchart of POCT Finished Products

What Makes Us Different?

Customization

Uncut sheet manufacturing can be more flexible than other manufacturing methods, allowing for greater customization of test kit components. This can be particularly useful for companies that need to produce specialized test kits for specific applications.